Thierry Dosogne/DigitalVision via Getty Images

Mainland Chinese medium- and heavy-duty trucks (MHDTs) have entered a bear market since mid-2021. Although the market staged a slight recovery following the easing of power shortages and injection of policy stimulus from late last year, unexpected headwinds brought by the Russia-Ukraine crisis and domestic Omicron outbreak plunged the market back into weakness in the second quarter of 2022. Amid pandemic-induced lockdowns in Jilin and Shanghai, production of MHDT hit the lowest reading for April in over a decade. In our May forecast, we downgraded the mainland Chinese MHDT production for 2022 by 5% to 1.13 million units, a decline of 23% compared with 2021.

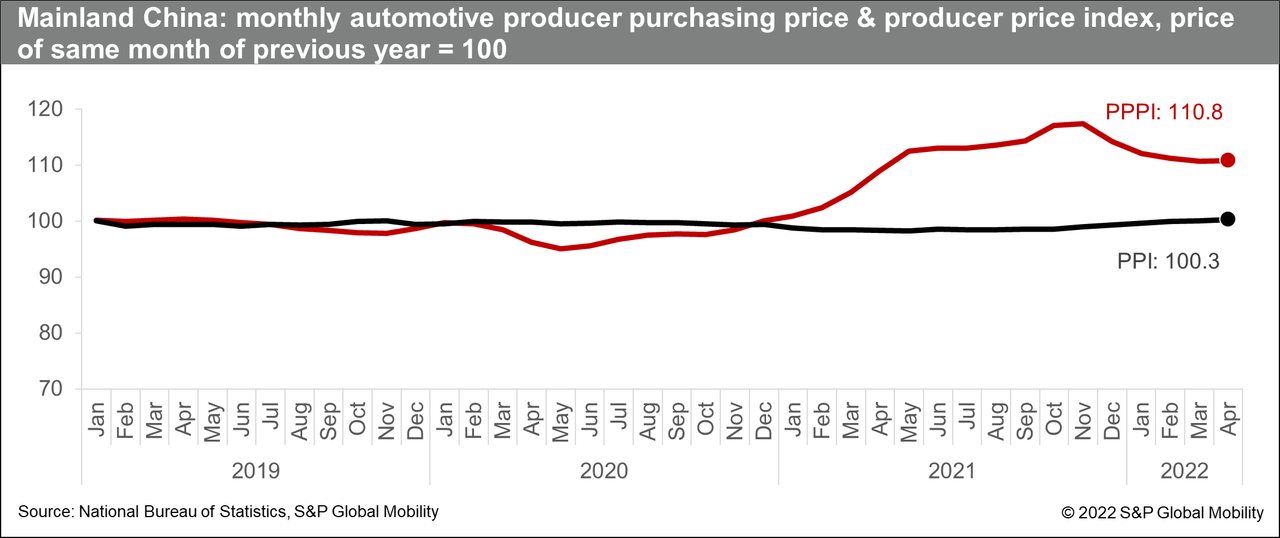

External Geopolitical Tensions Drive Up Producer Costs

As raw materials represent 20-30% of the cost of production for heavy trucks, raw material costs partially determine the profitability of truck producers. Owing to the global economic restoration from the COVID-19 scare, commodity prices have undergone an upcycle since late 2020. The rally gained more steam in the first quarter of 2022 with the outbreak of the Russia-Ukraine war. Specifically, the cold-rolled steel price that accounts for over 60% of the total raw material costs for a heavy truck surged by 3% in March 2022 from the level of January, expanding the growth to more than 40% as compared to the same period of 2020. Also, the diesel price raised by 15% and passed the RMB9,000 per metric ton mark through January-March 2022. In contrast, the movement of selling prices for heavy trucks were rather flat under slack demand, as fuel price inflation elevated the operating costs while oversupplied trucking constrained freight rate growth. As a result, the truck producers’ purchasing and selling prices logged significant differentiation, despite an increase in price of CN6-level models. Such weak inflation pass-through effect has made truckmakers to bear the brunt of the profit margin squeeze, especially after dumping of CN5-level trucks. With the Russia-Ukraine crisis expected to deepen into 2023, short-term truck production is therefore cut by around 25,000 units in the May outlook.

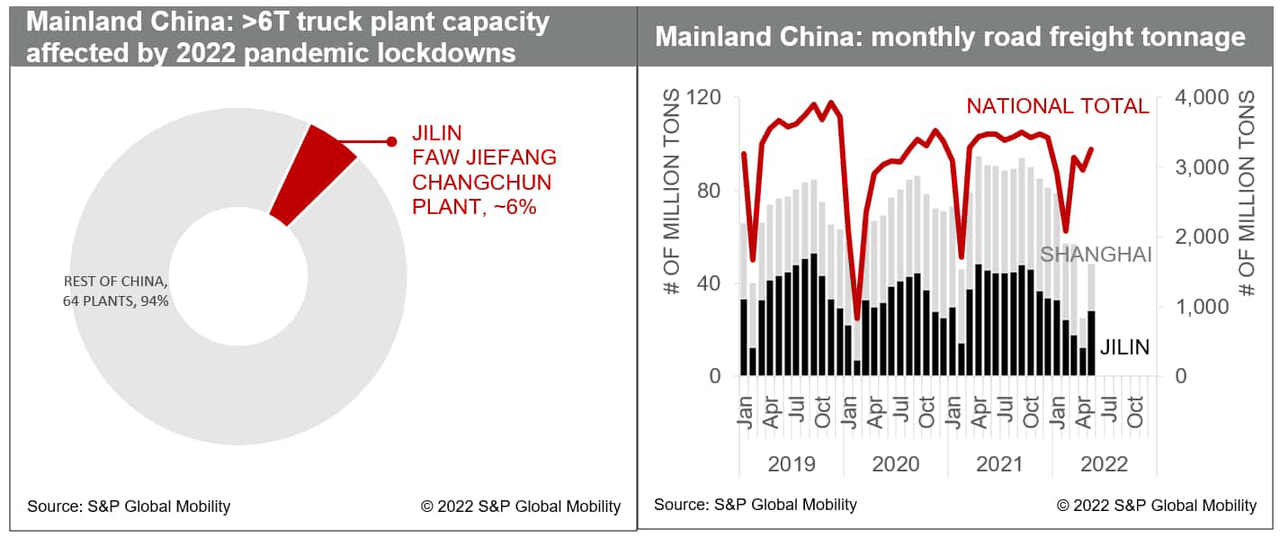

Internal Pandemic Resurgences Exacerbate Supply Chain Disruptions

The Omicron wave had triggered massive lockdowns in Jilin Province (March 11-April 28), Shenzhen City (March 14-20), and Shanghai City (March 28-May 31) since March 2022, resulting in widespread business disruptions and logistics snarls. Although there are few MHDT manufacturers in the epicenters of the pandemic, Changchun City and Shanghai City host over 40 big supply bases serving core components to mainstream models covering above 90% of truck production. Starting from mid-April, FAW Jiefang’s Changchun plant and most suppliers managed to resume work in the closed-loop system, but labor shortages under the mobility control disabled them to function at normal capacity. Meanwhile, rigorous containment measures such as traffic restrictions, nucleic acid test and quarantine requirements, as well as closure of toll stations pent-up road freight demand and caused wider repercussions of component shortages, which in turn dampening truck production. Under the circumstances, the total loss of MHDT production in the second quarter is estimated to reach 100,000 units. With ramping up efforts to smooth logistics and restore business, the work resumption rate of enterprises above designated size in Shanghai City improved to 96% by mid-June and will fully recover from July. Coupled with expansionary policies and sufficient capacity reserves, these could support MHDT production to pick up and offset the pandemic-induced loss in the second half.

A further downgrade to outlook is under assessment, as the government’s reliance on the “dynamic zero-COVID” strategy and capital outflows led by the Fed’s tightened cycle are likely to weaken business sentiment and subdue demand recovery. On the other hand, the rebuilding of dealer inventories of CN6-level MHDTs climbed from 280,000 units in early this year to 380,000 units by April, way higher than the typical rates of 150,000-170,000 units. Additionally, there were more than 70,000 units of CN5-level new trucks (sold as used trucks) remaining in the market, exacerbating de-stocking pressures.

Editor’s Note: The summary bullets for this article were chosen by Seeking Alpha editors.

Be the first to comment