jetcityimage/iStock Editorial via Getty Images

Followers of Tesla (TSLA) stock might be wondering when the new factory in Brandenburg, Germany will be coming online. After missing the original July 2021 date, Tesla CEO Elon Musk gave a new forecast for the end of December. That date has come and gone, and the factory still does not have a construction permit and although many analysts include Brandenburg production in their sales forecasts for Q1, there is no firm date for a start-up.

In this article, I take a look at the permitting situation and the status of the work on the site and reach the conclusion that volume production is unlikely before the second half of this year.

The permit to build the factory

The latest predictions from the German press are suggesting a possible date of the end of January for Tesla to finally be awarded a permit to construct the Brandenburg factory.

Although Tesla CEO Elon Musk said he was hopeful of acquiring a “permit to start production” last October, it appears that Tesla did not submit all the required documentation until late December, and delays in approval are at least partially a result of late submission of data.

Experts are currently reviewing the latest documents submitted by Tesla; this review is the final stage of the permitting process. The areas of concern appear to be the potential for pollution and the measures taken to prevent spills and discharges of untreated waste. Once the experts submit their reports, if satisfactory, the authorities will be able to issue a permit.

Tesla’s plant is located directly over a drinking water aquifer that supplies water to the area, and environmental groups claim that the amount of water allocated to the factory may result in a drinking water shortage. Two environmental groups have challenged the award of a water use permit, claiming that the granting of that permit was illegal. That case is now making its way through the Frankfurt courts with no assigned date for a hearing. It is not clear whether this court challenge will delay the final permit.

Temporary permits

Tesla is proceeding with construction based on a series of interim permits granted for parts of the work. Construction has moved forward based on those partial permits, and some of the factory equipment is now being tested, also based on interim, limited permits.

Tesla was granted an operating permit to test the stamping plant last September, and visitors to the plant saw the stamping operation in action during the October open day.

In late October another permit was granted to run operational tests on the paint shop (up to 250 vehicle bodies) and to test the casting machines over a period of 60 days. That permit also included permission to use a temporary hazardous materials store and temporary utilities and water treatment systems.

On January 7th, Tesla was granted another permit to continue the tests as follows (the referenced document is in German, the following is a brief summary with assistance from Google translate):

Permit to test:

- Stamping – Maximum 6,000 parts per week, 26,000 total

- Paint shop and Body in White– Up to 500 car bodies per week, 2,000 total

- Final assembly – continue performance testing, no specified throughput. This is probably testing and calibration rather than actual assembly.

The permit is granted subject to certain conditions, including:

- The test period is extended for a maximum of 8 weeks, which works out to 250 car bodies per week if the stated maximum is reached during the eight-week time frame.

- The permit includes the continued operation of temporary utilities.

- Tesla must submit schedules for each week of testing and report on the materials used and the emissions.

- Tesla is not permitted to use any of the parts and bodies made during the test period in saleable vehicles. Documentation and proof of disposal are mandated.

- Liquid wastes must be analyzed, and certified proof of disposal is required for hazardous waste.

The extension to the test period was requested by Tesla because the “parts and/or bodies joined as part of the system tests have a poor quality that deviates significantly from the specifications”.

The German authorities appear to be doing whatever they can to allow Tesla to proceed with construction and testing at the Brandenburg factory. However, they do not appear to yield when it comes to pollution control, water treatment, and hazardous materials.

Award of a permit does not mean production will start

Although permitting has been put forward as the reason why the plant didn’t start up on time, it is clear from videos taken at the site and posted on YouTube, that a lot of work remains to be done before the plant can reach volume production.

Paint Shop

The paint shop is operating with temporary services including compressors and a temporary process water cooling system that has been installed outside one of the doors of the main building. The photo below shows the temporary installations:

Temporary Utilities at the Paint Shop YouTube

Before the paint shop can be operated in its final configuration, the pipes that are running down the wall must be relocated to the adjacent pipe rack and across to the central utility building, which is not yet complete.

There is a similar but smaller arrangement of compressors and coolers outside the stamping plant.

Central Utility Building

The central utility building is itself still under construction, as shown in the photo below:

Central Utility Building YouTube

At the far end, you can see the process water coolers, they have been placed on their foundation, but none of the piping is installed. They sit outdoors adjacent to the central utility building.

In the foreground is the foundation for the central utility building; construction of the building structure has not started. Equipment to be installed inside the building includes chillers, air compressors, air dryers, and hot water boilers, all of which are essential to the operation of the factory. Two stacks have recently been erected to take the waste gas from the boilers, but so far none of the equipment in the area has been installed.

Water treatment plant

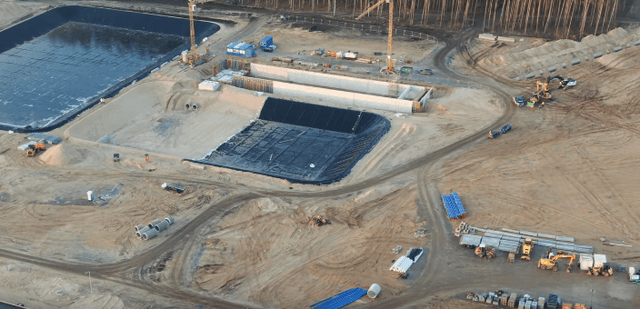

Adjacent to the central utility building is the water treatment plant, shown below:

Work on this area is barely started. Eventually, this building will house tanks, filters, and other equipment for the treatment of water from the paint shop skid cleaning process, the casting quench tank, the finished car leak tests, and other areas of the plant.

Permits issued in October mention that Tesla had to submit a revised design for the water-treatment plant. I believe that submission was part of the documentation handed over in December which is currently being reviewed. Some work on the water treatment plant building was allowed to start in November but completion is very likely delayed pending approval of the final design.

Miscellaneous incomplete areas

There is an extensive system of drains, retention ponds, settling basins, and pumping stations for dealing with stormwater at the site. This has been under construction for several months but is a long way from completion.

Part of the stormwater management system YouTube

Other areas that are visibly incomplete

The main building heating system is not functioning yet. Some heating and cooling units have been installed on the roof, but ducting is not complete. Temporary heaters are installed at various locations outside the doors of the building, blowing heated air inside.

Similarly, there is no heat in the drive unit building, which also appears to have no services. The pipe rack to the building is empty and it is unlikely that drive units can be made at this time.

A piling machine has recently appeared on-site in the area of the extended stamping plant, work on the extension may be starting soon. Tesla’s schedule submitted last July indicated a six-month time frame for construction of that section of work.

The hazardous materials warehouse has not been started. This is a 3,000 sq. m. building for the storage of hazardous input materials and hazardous wastes. Handling of hazardous materials is thought to be a subject of the documents currently under review and the delay in constructing those facilities is probably permit-related. Tesla has been operating a temporary hazardous material store while they have been testing the paint shop and casting facilities. However, a permanent facility will likely be required before the plant can start volume production.

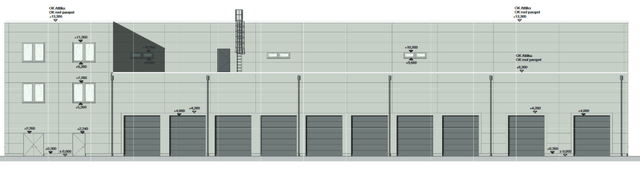

The fire station building has not been started. It is a three-story building as shown below:

Proposed Fire Station Tesla Documents Submitted for Approval

Videos of the construction site show an area that resembles a building site, not a finished factory. There are temporary storage structures and more tents than a boy scout jamboree. The area is littered with construction materials, piles of dirt, earth-moving equipment, cranes, trailers, and temporary offices. Roads, outdoor lighting, and parking areas are partially complete but a lot of work remains to be done.

Completion is months away

Tesla fans will no doubt remember the “start of production” of the Model 3, when Tesla rolled a hand-built car off the end of a fake production line for a publicity stunt six months before the real production line was finished. We might see something similar at Brandenburg once the building permit is issued. No doubt the award of the final permit will be accompanied by a fanfare of publicity and a sharp upward move in Tesla’s share price, but it does not signal the start of production.

Given the rigorous procedures for verification of safety and pollution control systems in the factory, I don’t imagine the authorities will be keen to allow real production to start without the water treatment plant, the hazardous materials store, and possibly the fire station. Those buildings are 4 to 6 months away from completion, assuming there are no more permitting delays.

I don’t expect to see meaningful sales from the Brandenburg plant until the latter half of the year. What that means for Tesla’s stock price is harder to predict. I see some bearish factors influencing the price in 2022.

- Delays in starting Brandenburg mean that Tesla sales could lag in Q1 and Q2

- BEVs will see margin pressures in 2022 from rising costs of input materials (Lithium prices have risen 500% since early last year, Nickel and Copper prices are higher, battery prices are trending upwards). However, legacy manufacturers will be reluctant to raise prices because they need BEV sales to meet their emission targets, competition will intensify.

- Production costs at Brandenburg are likely to be higher than Shanghai, even after transportation costs and import duties, and ramp-up costs in the second half of the year, at both Brandenburg and Austin, could put further pressure on Tesla’s margins

However, the biggest influence on Tesla’s stock price will probably come from a general movement of the market and a pullback in the prices of last year’s big gainers as the Federal Reserve tightens the money supply.

Tesla shares have had a strong run-up, but there is no realistic scenario that can justify their current valuation. Perhaps it is time for those who have enjoyed the ride up to follow the example of Tesla’s CEO, and take some profits off the table.

Be the first to comment